Clean-cut buildings, detailed windows, and beautiful fencing; these are only a few examples of what the model builder can do with their laser cutter and our laser board. At Lasersheets we are crazy about this material, not only because it is so easy to cut and engrave with your laser cutter. It allows you to apply the smallest details and the material remains strong, does not show any burn marks, and does not deform due to the heat.

Laser board is an ideal material for model building, but also for making stencils, or an overlay that you can bend or paint.

We think that laser board should get a prominent place in your workshop. Read more about the unique characteristics of this material, and about what you can do with it if you own a laser cutter.

What is laser board?

Laser board is a lightweight and thin (0.5mm or 0.9mm) piece of cardboard, soaked in resin. This resin makes it very strong and you can even add the smallest details without them breaking off. The heat of the laser cutter does not deform the material and also does not cause burnt or darkened edges.

For all these reasons, laser board is an ideal material for use in model building. There is no other material with which you can realise such fine details. With laser board you can create a façade with detailed windows and crumbled stones, a royal wooden staircase, or a beautiful walled front garden for your model design.

The characteristics of laser board

The possibilities with laser board in model building are huge. That is mainly because of the unique characteristics of this material.

The list below clearly shows how versatile it is.

- Laser board is thin and lightweight, yet very strong.

- It is flexible and it can be bent if need be.

- You can paint and glue laser board.

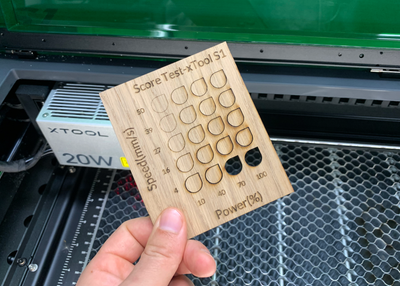

- It is a material which can be both cut as well as engraved.

- There is no other material into which you can laser such fine details.

You can make this with laser board

Our laser board is produced by PolyBAK and can of course be perfectly processed with the laser cutter. So, what can you do with it?

1. Fine engraving and cutting

As mentioned earlier, laser board is very strong. You can use it for cutting the most detailed images. These can be parts of your model, but also a drawing you made or a picture you edited.

The petals of flowers are cut out perfectly, your historic facade receives unprecedented detail (down to hairlines in the stones) and even the antennae and legs of insects remain intact.

2. Stencils

Laser board is also a fine material to use for making stencils. You can use stencils for placing images or texts on walls and items. It is ideal for repeatedly applying a logo, for example. Create a stencil with your laser cutter and spray paint your own logo on all your products.

The advantage of stencils is that they can be reused. By using multiple stencils you create an image with different layers and colors.

3. An overlay for your final product

Our PolyBAK laser board is also widely used as an overlay on another material. It can be easily painted, bent, and glued. Engrave an image into the laser board and place it on the front of a cupboard, on a piece of furniture, on a lamp shade, or any other item that you made.

Laserboard at Lasersheets

We think that laser board is a fantastic material for the laser cutter and that is why we offer it to everyone eager to benefit from it. Our PolyBAK laser board is regularly purchased by model builders and hobbyists. That is why we also sell it in smaller packages, which can simply be delivered by regular post. We offer pallets to our large-scale customers.

Do you have any remaining questions about laser board? With Lasersheets and our subsidiary Snijlab we have more than 12 years of experience in using and selling laser materials. Laser board belongs to our personal favourites. Contact us to speak about your next laser project and the ideal materials to perfect it.