Foam & rubber plate

Filter and sort

7 products

Foam and rubber suitable for laser cutters

At Lasersheets, we offer various types of foam and rubber for use in your laser cutter. These materials differ from wood and serve various purposes. In our selection, you'll find a diverse range of hard foam (polyethylene foam), soft foam (polyether foam), neoprene, silicone, and CR rubber.

Choosing the right foam and/or rubber for your laser cutter is difficult. Some materials require a higher wattage machine, for example, or lenses with a longer focal length. The cutting results are also different.

To help you order the right foam or rubber from our online store, we share all our knowledge and experiences with this versatile and interesting material for your laser cutter.

Did you know... you can get rid of sooty, dirty and sticky edges if you wash silicone and CR rubber by hand, in the washing machine or dishwasher?

Our foam and rubber range and properties per material

We offer 5 types of foam and rubber, all suitable for your laser cutter. Some of them can also be engraved. These materials are available in various sizes and thicknesses and have received the LaserGrade quality mark.

Additionally, each foam and rubber sheet comes with different advantages and disadvantages, and not all of them are suitable for every laser cutter. We discuss all the options (hard foam, soft foam, neoprene, silicone, and CR rubber) to help you make the right choice.

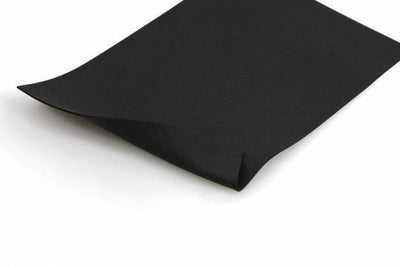

1. PE rigid foam (LaserGrade)

PE stands for polyethylene and this is the most purchased and sought-after type of foam for the laser cutter. This black foam is often used for flight cases, but it is also recommended for the laser cutter.

Pe foam comes out beautifully from the laser cutter. You can either laser cut or laser engrave it. The lasered edges become neat, sleek and clean.

Our high-quality polyethylene foam has the following features:

- The cells are closed, so it does not absorb water and is airtight.

- PE foam is somewhat heavier (29 kilos per cubic meter).

- Pe foam boards are elastic, resilient and temperature stable.

- It is a black foam.

In the Lasersheets webshop you will find standard PE foam, but also acoustic self-adhesive and oil-resistant foam. This has a specific application and is widely used for acoustic insulation and as a damping material.

Our customers use standard pe-foam for the following projects:

- Inlays for suitcases, tool boxes and drawers.

- Product packaging interiors.

- Logos and signing.

We sell polyethylene foam and acoustic foam in the following dimensions and thicknesses.

- Dimensions: 20 x 30 cm, 60 x 30 cm, 60 x 60 cm, 90 x 60 cm and 120 x 60 cm

- Thicknesses: 5mm, 10mm, 15mm, 20mm

- Dimensions: 16 x 25 cm, 50 x 25 cm, 50 x 50 cm, 100 x 50 cm

- Thicknesses: 15 mm

Note: do you want to laser a thicker PE foam sheet? Assume that for a PE foam sheet of 15 or 20 mm thick you need a 90W laser machine. Polyethylene foam with a thickness of 5 and 10 mm can be used in a laser cutter with a lower power.

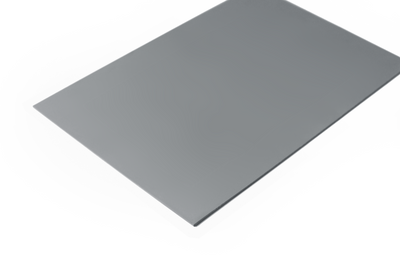

2. Soft foam (LaserGrade)

Soft foam (polyether foam) is also a favorite among our customers. You may recognize it as mattress foam, but it is also suitable for the laser cutter. You can cut shapes out of it, for example. Many customers use it as a budget-friendly alternative to PE foam.

Please note that soft foam does not come out of the laser cutter as cleanly as PE foam. Sometimes the edges become light brown, but this is hardly noticeable. Depending on your laser cutter, the edges can sometimes become slightly slanted, especially with the 40mm thick variant. Soft foam is not very suitable for engraving.

These are the features of our high-quality soft foam:

- The cells are open, allowing water and air to pass through.

- It is lighter in weight than PE foam (20 kg per cubic meter).

- It is gray in color.

- It is less suitable for detailed shapes.

Our customers use soft foam for similar applications to PE foam.

- (Temporary) inlays for suitcases, drawers and chests.

- Protection of vulnerable objects.

- Inside of product packaging.

The name says it all, but soft foam is softer than hard foam. We sell it in the following dimensions and thicknesses.

- Dimensions: 20 x 30 cm, 60 x 30 cm, 60 x 60 cm, 90 x 60 cm and 120 x 60 cm

- Thicknesses: 20 mm, 40 mm

Please note: do you want to cut soft foam with a thickness of 20 or 40 mm in your laser cutter? Then this is only possible if it has a power of 90W and 3-inch or 5-inch lenses.

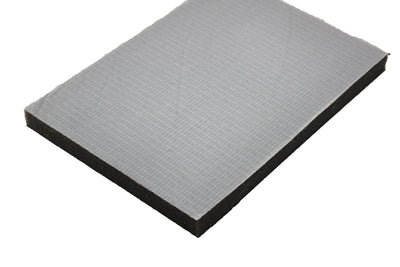

3. Neoprene (LaserGrade)

You may know neoprene from wetsuits and other water sports clothing, but it can also be used in the laser cutter. Our neoprene, unlike clothing, has no textile on the inside.

Neoprene is a type of foam rubber that comes out nicely from the laser cutter. The edges are sleek and straight, hardly showing any discoloration.

These are the features:

- Closed cells, so it is waterproof and airtight.

- Flexible and bendable.

- Wear-resistant.

- Good insulation.

What can you use neoprene for? Many of our customers buy it for technical applications, such as seals, damping and insulation.

You can order neoprene foam rubber from us in the following dimensions and thicknesses:

- Dimensions: 16 x 25 cm, 50 x 25 cm, 50 x 50 cm, 100 x 50 cm

- Thicknesses: 1mm, 2mm, 4mm, 8mm

Neoprene can be used in most laser cutters. No special skills are required to cut neoprene.

4. Silicone (LaserGrade)

Silicone is a rubber. It is not the most commonly used material for the laser cutter, but it can produce very interesting results. It is widely used in the food, medical and pharmaceutical industries.

The silicone rubber edges come out of the laser cutter sticky. But that can be easily solved if you wash it in the washing machine or dishwasher. Then it will look like new again and you can use it for your project.

Silicone rubber has the following interesting characteristics:

- Strong, tear-resistant, very stretchy and tough.

- Wide temperature range: -60° C to +220°C.

- Resistant to sunlight, various gases and reasonably resistant to chemicals.

- Water repellent.

The applications of silicone rubber are somewhat limited and it is also an expensive material. But our customers use it a lot for seals, insulation, impact protection, as a baking mat (temperature resistant up to 220°C) or as a coaster.

We sell silicone rubber in different sizes and thicknesses.

- Dimensions: 20 x 30 cm, 60 x 30 cm, 60 x 60 cm, 90 x 60 cm and 120 x 60 cm

- Thicknesses: 1mm, 2mm

Please note: silicone rubber can only be cut with a laser cutter with a power of at least 60W.

5. CR rubber (LaserGrade)

The last material we offer in our foam and rubber category is CR rubber. This is a multifunctional type of rubber. Our CR rubber sheets are black through and through.

CR rubber can be cut by most laser cutters, but the edges are often sooty and dirty afterwards. You just need to wash this - by hand, washing machine or dishwasher - and your cut CR rubber will look like new again.

These are the most important features of the high-quality CR rubber from our webshop.

- Very flexible

- Weatherproof

- Wear-resistant

- Multifunctional

CR rubber is an ideal choice if you need rubber to cut shapes. Unlike silicone rubber, you do not need a high-power laser cutter. What can you use it for?

- Seals

- Flange gaskets

- Gaskets

In our online store you will find black CR rubber sheets with the following dimensions and thicknesses:

- Dimensions: 20 x 30 cm, 60 x 30 cm, 60 x 60 cm, 90 x 60 cm and 120 x 60 cm

- Thicknesses: 1 mm

The LaserGrade quality mark

All our foam and rubber sheets and sheets for the laser cutting machine have the LaserGrade quality mark. This means that we can guarantee that our materials are suitable for the laser cutter. You don't have to worry about toxins being released while you work or edges burning.

The LaserGrade quality mark guarantees us, and therefore also you, that the materials have been tested for the laser cutter and declared suitable for laser cutting and engraving. Lasersheets specializes only in materials that can be used in the laser cutter, and our rubber and foam are no exception.

What should you pay attention to when buying foam and rubber for the laser cutter?

Now that you know which types of foam and rubber we offer for the laser cutter, we will give you some tips on points to take into account when purchasing one.

1. Choose foam and rubber that fits your laser cutter

Not all laser cutters can cut foam and rubber without problems. We have already mentioned this above under the different materials, but because this is very important, here is a summary of our recommendations.

- PE foam: to cut hard foam sheets with a thickness of 20 mm you need a 90W laser machine.

- Soft foam: to cut soft foam of 20 mm or 40 mm thick you need a laser machine with a power of 90W and 3-inch or 5-inch lenses.

- Silicone: to cut silicone rubber you need at least a 60W laser cutter.

2. Not all foam and rubber are suitable for engraving

As you know, the foam and rubber from our stock carries the LaserGrade quality mark. This means that it has been declared suitable for laser cutting and engraving.

There is 1 exception to this that is important to know. Soft foam can be engraved, but the results are much less beautiful than if you used PE foam.

3. Foam and rubber for beginners

If you're a novice laser cutter and want to work with rubber, we recommend starting with neoprene rather than CR rubber or silicone.

Neoprene is cut very cleanly by most laser cutting machines, while the edges of silicone and CR rubber can become dirty, sticky, and sooty. Start with neoprene, and if you find it suitable, you can always explore specialist silicone rubber or multifunctional CR rubber later on.

Buy foam and rubber at Lasersheets

Buy your PE foam sheets, soft foam, and rubber at Lasersheets. All our materials are suitable for laser cutting and engraving. We supply to entrepreneurs, designers, technical schools, fablabs, and makerspaces, among others. Because we also send small quantities by post, we are also an ideal supplier for hobbyists and small consumers.

Are you still unsure or do you have any questions? Please contact us and we will help you further. With more than 12 years of experience as a laser cutter with our sister companySnijlab , we understand the challenges of rubber and foam, but we also see so many unique possibilities.

Laser cutting is our hobby and specialty, so view our extensive range and be surprised by the versatility of foam and rubber in your laser cutter.